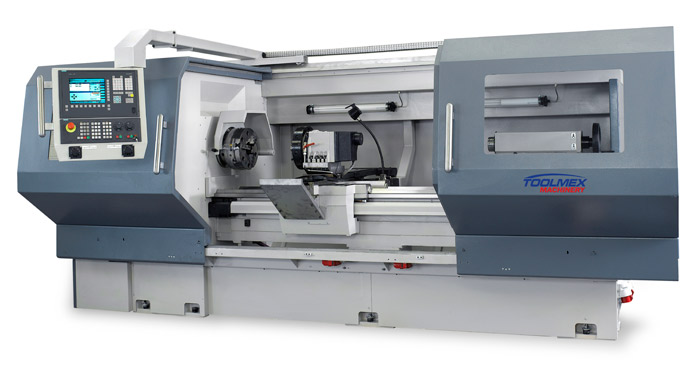

Whenever you are seeking high voluminous

metal parts or superbly blended metal parts, you need horizontal machine

centres for sure. There are some certain advantages you can get after using

these devices like you can get the right kind of metal parts no matter how much

complex these drawings are. Now have a look at what are the benefits you can

get from these horizontal machines:

Survey says these

horizontal machine tools for sale are very much useful. This is the reason a large number of people using

it without doubt.

- An interesting fact is all the modern horizontal centres have four axis machines in it. Just 1 degree increment is enough to turn and lock the horizontal table. You have the freedom of turning 20 degrees for cutting odd angel faces or for drilling a hole. If you want anomalous angles in complex metal set ups, the right suggestion is trying the horizontal machine centres.

- With these gadgets, chip controlling is very much easy. When you are cutting large metal parts with big pockets, using the machine will give you some certain advantages. The horizontal device is going to assist you by cutting large metal parts.

- These machineries are equipped with a large pallet and square metal column and this is known as tombstone. Custom fixtures are bolted on each of the four sides of the tombstone.

- Flexibility. Yes, this word suits best with these horizontal machines. The special feature that is known as flexibility can be accessed in the face of a tombstone. With switching the right program, you have the option of saving your time from making repeated works again and again.

- Customisation is another benefit you are going to get from the devices. If you are not happy with a single or double pellet, you have the option of using even six pellets.

These horizontal machine

centres come with some certain criteria. If the owner want to set up a small

production place in home, it will be advisable to use these devices.