Industrial

work sites always come with some sort of hazards. It is the responsibility of

the factory owners to provide an adequate level of security to the workers to

boost productivity. In manufacturing and other heavy metal industries, workers

are usually exposed to the powerful and sharp blades of various machines that

can kill, injure or maim them forever. The emergence of growing technology has

made the task of exploring alternative secure measures quite easier.

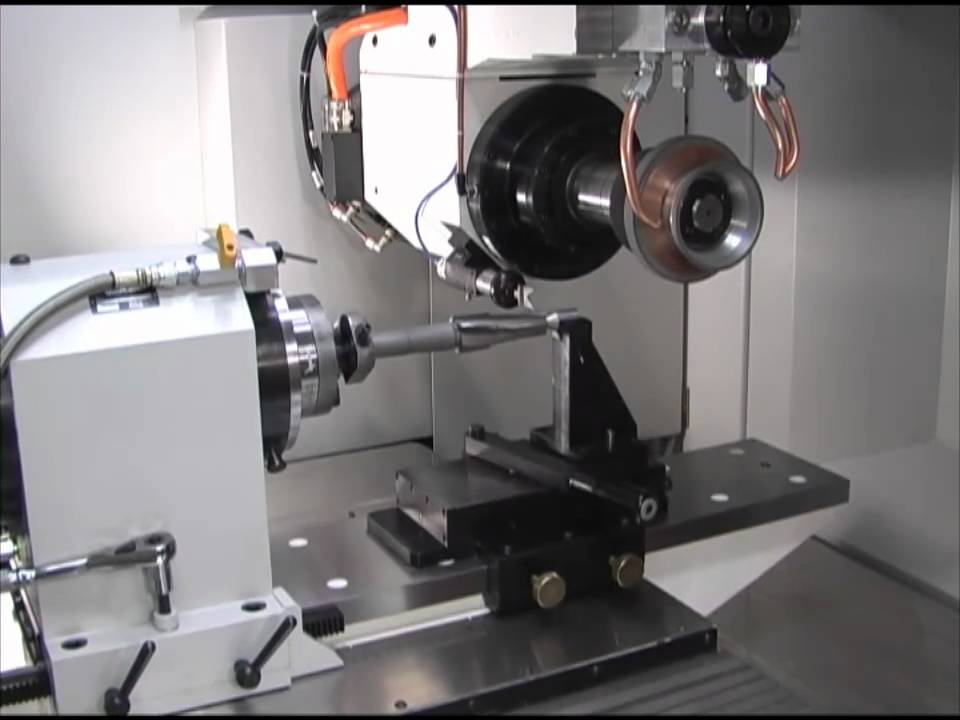

Machine

guarding system is one such marvellous piece of wonder of the modern precision

engineering science. This system mainly unleashes benefits such as:

Securing device:

The new technology completely prevents the scope of tampering or manipulating

the spare parts and configurations of the machine by any measure. Once you

install such system even the specialized personnel of your factory will not be

able to damage or reverse the functioning of a costly machine.

Prevent contact:

Installing the system of machine guarding will prevent the workers of your

factory to easily avoid injury from the pointed ends of any machine. It will

help them to work without any fear of injury while performing fabrication,

milling etc.

Smooth machine operation: You can now run any powerful machine either manually or in

automation without interrupting production. It is because such system always keeps

the essential CNC lathes for sales

in good conditions even after the long period of utilization.

Prevent debris accumulation: Your factory machines will not encounter the fall of debris or

splatter during the time of maintenance or constant operation to boost the

volume of production. It is because such system is bundled with the adjustable

guards that can be smoothly adjusted depending on the work conditions and

volume.