Metal

industry is expanding rapidly due to the emergence of latest processing and

manufacturing technologies. For keeping a steady pace with the growing

requirements of the clients, many companies are now investing heavily to

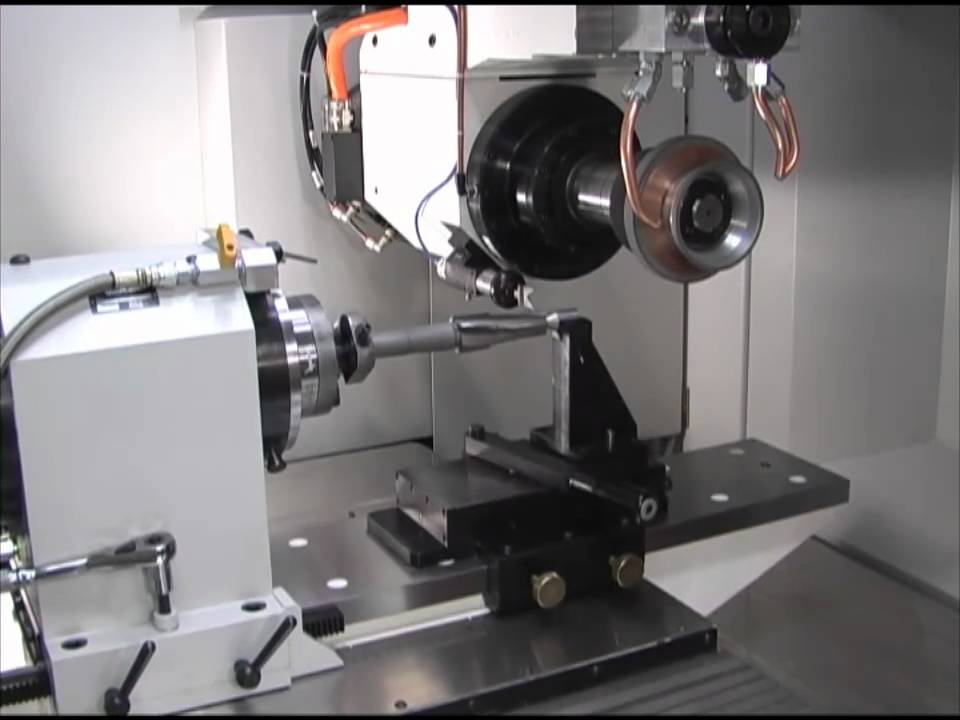

install 5 axis CNC machines of distinct configurations. Such machines are based

on latest computer-based application and always activate on time to execute the

command of the users.

There

are various benefits that come with the installation of CNC machining of 5 Axis

which mainly include points such as:

- Reduce waste generation: Once installing a 5 axis CNC machine in the work-site there is not only reduction of residual waste generation but also keep the interior air of such chamber completely clean. Such machines pretty swiftly perform the task of cutting without creating any sound or smoke.

- Handling complex parts: This machine also comes with the reputation to fix or attach complex spare parts in any metal object without slowing down the speed of work. Using this machine, engineers can easily install tiny spare parts in the remote corner of a metal or non-metal product without committing any mistake.

- Save drilling time: This CNC lathes for sales always take a very less time in creating holes in various angles. This machine comes with the powerful motor head which can automatically drill holes with enough power to ensure a timely completion of other phases of manufacturing.

- Curtail vibration rate: This advanced machining system also comes with the series of short cutters that actually help to curb vibration while drilling holes to save much time to ensure a perfect finishing of an assignment with less labour. Such machine also eliminates scope of collision between different motor parts while performing heavy activities.

A 5-axis

machine also provides surplus scope of innovation that ultimately boosts the

industries of heavy machineries and accessories.

No comments:

Post a Comment